Design of a Complex CIP Skid for a Pharmaceutical Customer

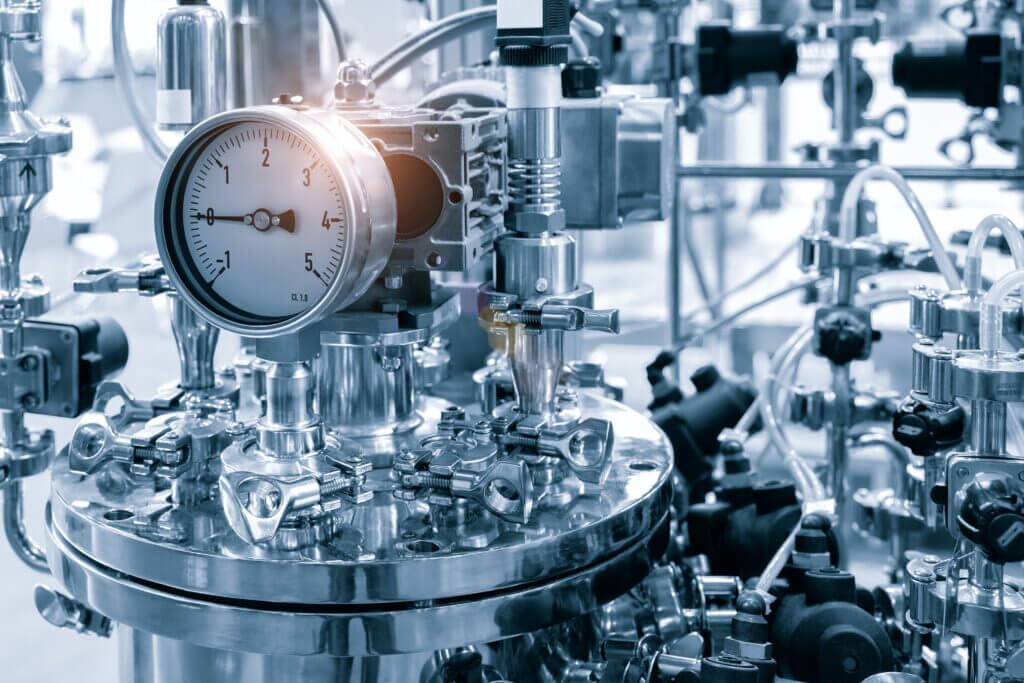

Protechnicon has successfully designed a complex Clean-In-Place (CIP) skid for a leading Pharmaceutical customer. This skid is used for cleaning pipes and tanks used in the production of medicines. The project had several technical challenges that we solved with precision and expertise.

Challenges and solutions

- Developing P&ID into 3D Model: We created a complete 3D model from a Piping and Instrumentation Diagram (P&ID) and component list, which was then developed into detailed 2D workshop drawings.

- Beperkte Transportroute: De skid moest door een beperkte transportroute naar de uiteindelijke locatie worden gebracht. We therefore designed the skid in segments that could be easily assembled on-site.

- Limited Space: The space available for the skid was very limited. Our design took into account the installation requirements of pharmaceutical piping and components, with each component accurately positioned to make optimal use of the available space.

- Piping design: Placing the ASME-BPE pipework completely at a slope was essential for efficient cleaning, which made the design extra complex.

- Advanced 3D Scanning: We used advanced 3D scanning technology when creating the 3D drawings. This allowed the pipework connecting to the CIP skid to be delivered completely prefabricated, resulting in minimal downtime during installation.